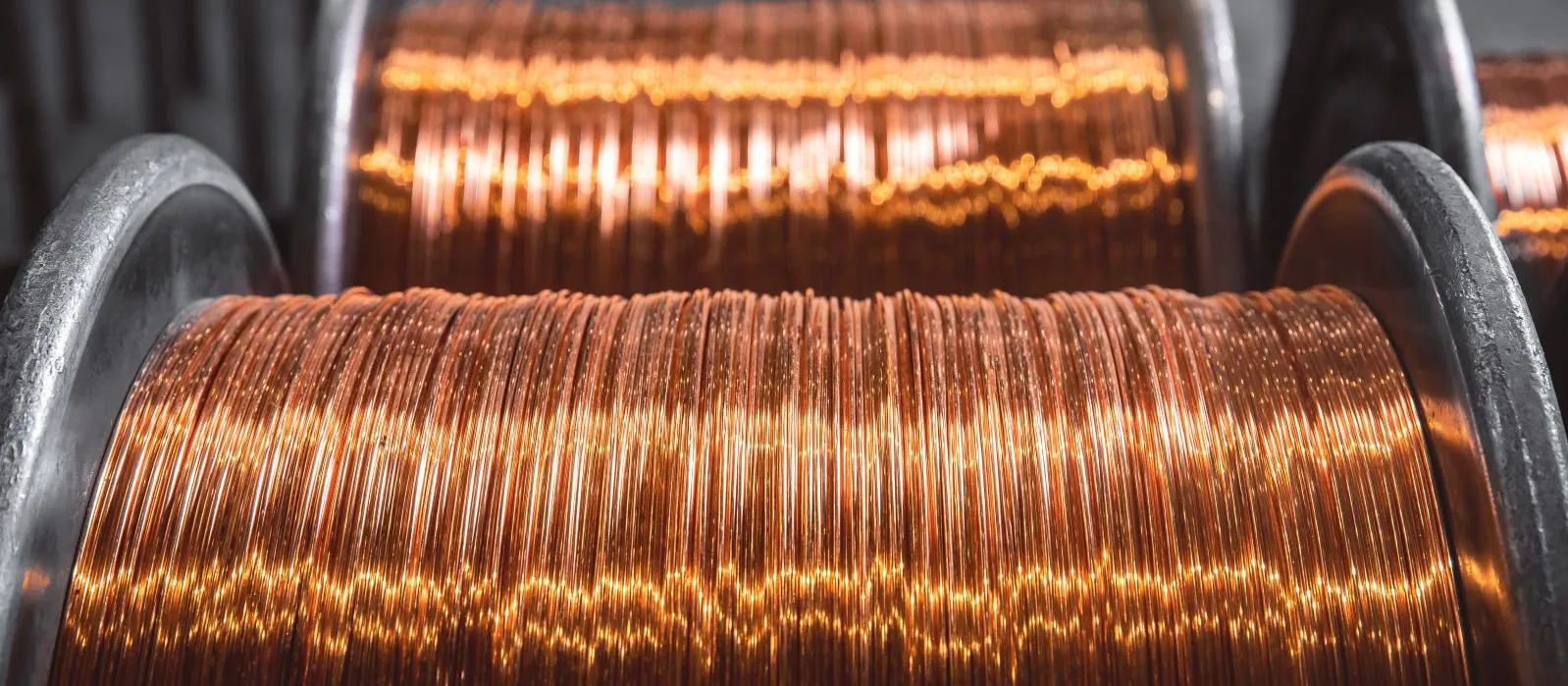

Precision matters at every stage of magnet wire production. From winding to shipment, dependable handling and packaging play an important role in maintaining product quality and operational efficiency. High-speed processes and sensitive insulation coatings place added demands on packaging systems. The right magnet wire spools help maintain stable winding, limit handling issues, and preserve wire integrity throughout production and transport.

With decades of experience supporting high-precision industries, Sonoco delivers engineered packaging solutions that help manufacturers operate with confidence and consistency.

The Challenge Magnet Wire Manufacturers Face

Performance at the winding line depends heavily on spool stability, dimensional accuracy and material durability. Even small variations can interrupt operations, resulting in downtime, rework, or product loss.

Magnet wire insulation coatings, including those used in RT 24 x 13/17/32-type applications, add further complexity. These coatings must remain intact through winding, handling, storage and shipping. Abrasion, vibration and environmental exposure can compromise functionality well before the wire reaches its end use.

As production speeds increase and quality expectations rise, manufacturers are taking a closer look at how packaging choices influence performance across the entire process.

Common Packaging Challenges and Their Impact

| Operational Challenge | Potential Impact on Production |

| Inconsistent spool dimensions | Winding instability and line interruptions |

| Flange deflection under tension | Uneven payoff and increased risk of wire damage |

| Insufficient insulation protection | Coating abrasion during handling or transit |

| Packaging not aligned to line speed | Reduced efficiency and increased rework |

Spool design, material selection and protective packaging all contribute to maintaining reliability from the winding line through delivery.

Sonoco’s Solution: Precision-Engineered Magnet Wire Spools and Reels

To meet the demands of modern wire manufacturing environments, Sonoco offers a portfolio of magnet wire spools designed to perform under high-speed, high-precision conditions.

Sonoco’s plastic spools for wire manufacturing are engineered for dimensional accuracy and material strength, supporting reliable performance in demanding production environments.

Key advantages of Sonoco magnet wire spools include:

- Dimensional accuracy that supports consistent, high-speed winding

- Through-bore construction for efficient loading and compatibility with winding equipment

- Carefully positioned parting lines that help reduce snagging during de-reeling

- High tensile strength materials designed to withstand demanding production environments

- Rigid flange design that helps prevent deflection under tension

- Reusable construction that supports long-term efficiency and waste reduction

Together, these design elements support smoother payoff, faster line speeds and fewer unplanned interruptions. The result is a reusable, dependable packaging solution that helps maintain wire quality while keeping production moving.

For manufacturers like Magnekon, where precision wire and advanced insulation systems require controlled handling, Sonoco’s spools offer a practical response to real operational demands.

Additional Industrial Wire Packaging Solutions

Beyond spools and reels, Sonoco provides protective packaging for magnet wire that helps safeguard product integrity through handling, storage and shipment. Solutions including tubes, endwalls, cores and carrier systems help stabilize coils, limit movement and shield sensitive insulation from abrasion and environmental stress.

These industrial wire packaging solutions scale to meet a wide range of production and logistics needs. From lightweight plastic reels used in precision winding applications to heavy-duty core systems built for bulk shipments, Sonoco supports manufacturers across different volumes, formats and distribution channels.

What sets Sonoco apart is the ability to tailor packaging solutions to specific line requirements and transportation conditions. By aligning packaging design with operational realities, Sonoco helps wire manufacturers protect product quality while maintaining efficiency from production through delivery.

Why Manufacturers Trust Sonoco

Manufacturers trust Sonoco because integrity, service, accountability, teamwork and respect guide every solution we deliver. These values shape how Sonoco partners with customers and how packaging solutions are designed, tested and supported. From plastic reels for wire to complete packaging systems, Sonoco focuses on practical solutions designed for real-world production environments.

That trust is built on clear advantages, including:

- Global manufacturing capabilities supported by responsive, reliable supply

- Rigorous testing and quality control that promote repeatable performance

- Sustainable material options that help reduce waste and support long-term goals

- A collaborative, customer-first approach centered on problem-solving and partnership

Ready to Move Forward with Confidence?

Packaging plays a critical role in maintaining wire quality and supporting dependable production. With engineered magnet wire spools and a full range of industrial packaging solutions, Sonoco helps manufacturers meet today’s demands while preparing for future growth.

Sonoco invites wire and cable manufacturers to start a conversation about their specific needs. From exploring custom spool designs to evaluating trial or sample options, our team is ready to collaborate. With scalable solutions and decades of experience, Sonoco supports reliable growth for magnet wire producers at every stage of production.

Frequently Asked Questions About Sonoco Wire Spools

How do manufacturers choose the right spools for high-speed wire winding?

The right spool depends on line speed, tension and coil structure. Sonoco’s plastic spools are engineered for dimensional stability, smooth winding and consistency across demanding, high-speed operations.

What types of packaging best protect magnet wire insulation during storage and transit?

Insulation is safest when packaging reduces friction, vibration and compression. Sonoco provides protective solutions—including tubes, reels, endwalls and cores—that keep coils secure and preserve coating quality.

Why are plastic reels preferred over traditional materials in wire and cable production?

Plastic reels deliver predictable, repeatable performance. They resist cracking, maintain uniform dimensions and support faster line speeds. This consistency helps manufacturers reduce downtime and maintain product integrity.