Sustainable Products

What makes packaging better?

Is it the design? The functionality? The materials—or what happens after use? At Sonoco, the answer is all of the above.

Our top-to-bottom, life cycle–driven packaging process accounts for every detail – the material sourcing and manufacturing to consumer use and end-of-life. This holistic approach makes us a sustainable paper and metal packaging leader — looking beyond what we make to evaluate the impacts on our lives.

- Value Chain

- Lifecycle Assessments

- Designing for Sustainability

Value Chain

In 2024, our first Corporate Sustainability Reporting Directive (CSRD) aligned double materiality assessment (DMA) gave us a broader look at the risks and opportunities for our company as a whole. From there, we charted our entire footprint – what happens upstream (shipping and warehousing) to raw materials and those supplied to us; to the operations involving manufacturing, workforce and management functions; and lastly, the impacts downstream. This involves the final leg of our journey – shipping to customers, warehousing stored goods, how customers handle our products and what happens when consumers buy, then no longer use them.

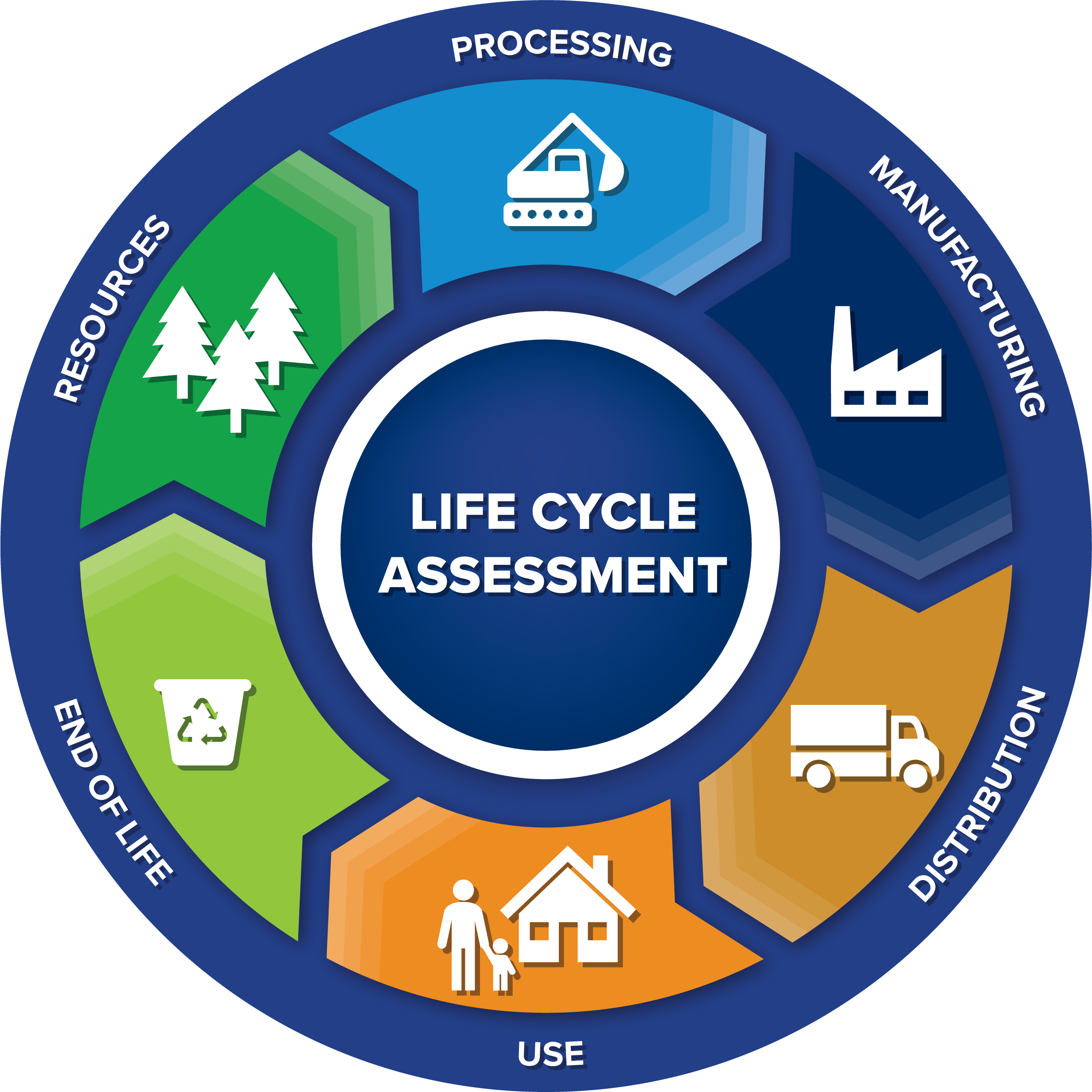

Lifecycle Assessments

Product Carbon Footprint Goal

Product Carbon Footprint Goal

The results from our potential value chain impacts come from life cycle assessments (LCAs), presented to our Research & Development and Material Development teams. The information helps us evaluate raw material choices, transportation and end-of-life impacts for recycling, landfilling and composting. LCAs also provide comprehensive product carbon footprint (PCF) data to customers and show us where we can best limit our carbon emissions.

2030 Product Transparency Commitment

Sonoco has established a goal of automating the carbon footprint assessment capacity for 75% of our global portfolio at product level by 2030.

Designing for Sustainability

Innovation starts in our world-class research & development (R&D) centers across the U.S. and Europe, where Sonoco engineers, scientists and customers collaborate to improve performance, recyclability and speed-to-market across both paper and metal packaging solutions.

Our Metal Packaging Technical & Engineering Center in Columbus, Ohio and R&D Centre in Wantage, UK offer advanced testing, food processing areas and pilot-scale production to accelerate innovation and assess real-world manufacturing conditions.

On the paper side, our Hartsville, SC R&D lab evaluates new fiber sources for repulpability and runnability across tubes and cores. In Hockenheim, Germany, our R&D center helped develop the widely recyclable paper-bottom Pringles® can—recognized by 4evergreen’s “Circularity by Design” guidelines, an award-winning packaging expanding into U.S. markets.

Together, these sites reflect our commitment to building sustainable solutions that work across regions, categories and value chains.

Advancing a Circular Economy

How does Sonoco promote circularity in packaging designs to reduce waste and mitigate impacts on our air and water systems? We work closely with customers to introduce a wide range of recyclable products and sustainability sourced materials, while partnering with leading advocacy organizations to promote recycling initiatives and increased on-pack labeling claims for a variety of packaging formats.

Sourcing Sustainable Materials

Sonoco Fiber

Our paperboard mills use 100 percent recycled fiber, representing many of the sites participating in our Triple Chain of Custody Fiber Certification program. Under this program, several mills and packaging converters can make certified, sustainable claims about the fiber sourced for their respective products, and our sites are certified under the following:

- Forest Stewardship Council® (FSC®), FSC-C123349

- Sustainable Forest Initiative® (SFI®), SFI-00390

- Programme for the Endorsement of Forest Certification (PEFC), PEFC/29-31-248

www.forests.org SFI marks are registered marks owned by the Sustainable Forestry Initiative. Look for our FSC certified products!

Sonoco Metal

We work closely with our steel suppliers to promote decarbonization and responsible material sourcing and third-party certification, primarily through ResponsibleSteel, to verify supplier practices align with our Scope 3 emissions goals, especially since steel production generally contributes to our activities upstream.

Sonoco Suppliers

In addition to our certified materials, we also regularly engage with suppliers to promote sustainability commitments overall. To learn more about working with Sonoco, visit our Suppliers page.

Sonoco hosts the Supplier Sustainability and Performance Awards at our Sonoco Supplier Conference. This is where we award select companies for demonstrating excellence in the areas of social, economic and environmental sustainability. Past recipients have included Kemira, NALCO Water, IPL Schoeller, and Ahlstrom.

Sonoco Paper Container

A rigid paper container comprised of 100% cardboard, including the bottom end, contains 90-95% recycled content. Recognized by the Packaging Association (PAC) at its 2024 PAC Global Awards, earning PAC Best in Class for Sustainable Package Design — Package Circularity and PAC Award of Distinction in Package Innovation Design — Technical.

Sonoco’s American Duster and Spray-X® Duster

A lightweight, two-piece aerosol developed in partnership with Technical Chemical Company (TCC) just two years before product release. Received the Innovation in Packaging Excellence award at the 2024 AAPEX Show (Automotive Aftermarket Products Expo) for a new product line of compressed-air dusters, American Duster and Spray-X® Duster.

Sonoco Metal Packaging EMEA Ecopeel™ and Horizon™

An easy-to-open canned food solution using less material, Ecopeel™, and a sustainable lightweight overcap, Horizon™, from Sonoco Metal Packaging EMEA. Both earned transformation awards at the Oscar de l’Emballage 2024 ceremony for innovative advancements, with Ecopeel winning overall.

Questions?

To learn more about our Better Packaging. Better Life.® commitments and packaging solutions, talk to a member of our team!