Film Cores

Film Cores

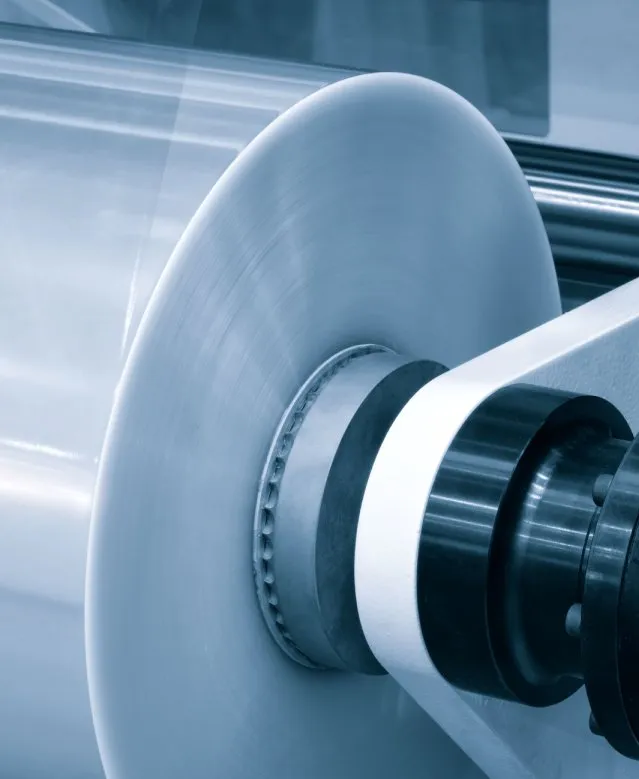

Efficiently wind and unwind with Sonoco’s film cores. We utilize our industry-leading technology, durable plastic, high-quality recycled paperboard and proprietary adhesives to produce cores that meet specific performance criteria and resist chew-out, decreasing landfill waste and fees as well as increasing efficiency across converting applications.

- Sonoco High-Performance Film Cores

- Stretch Film Cores

- Shrink Film Cores

- General Film Cores

Sonoco High-Performance Film Cores

Minimize surface markings and improve winding and unwinding characteristics with Sonoco’s line of high-performance film cores. Ideal for clean-room applications, our fiber and plastic cores handle your specific roll weights, winding and packaging configurations with a range of surface qualities and characteristics that optimize core performance for thin metallic foils, graphics/self-adhesive films and more.

Stretch Film Cores

Improve runnability and lower costs with Sonoco’s paper mill cores. We set the standard for performance with a complete line of graphic paper, containerboard, paperboard, tissue and towel, pulp and nonwoven, and newsprint cores. Leveraging our industry experience and cutting-edge technology, we customize core products for your specific applications, equipment and processes.

Shrink Film Cores

Match your specific strength and performance needs. Sonoco designs shrink film cores to eliminate radial pressure and protect the internal diameter integrity, protecting from chewout, core length growth and other damage. Designed for efficient winding and unwinding, our cores streamline your manufacturing process and decrease manual labor costs.

General Film Cores

Wind and unwind more efficiently with cores engineered to fit your product's unique properties. Designed with Torque Transmission (T2) technology to enhance your circularity initiatives, our fiber and plastic cores incorporate recycled materials and reduce landfill waste from core damage that can lead to profit loss, safety issues, machine downtime and decreased productivity.

Eliminate Chewout with T2 Technology Enhanced Cores

Get rid of the hassle, risk and expense of core chewout with Sonoco’s Torque Transmission or T2 technology enhanced film cores. Through in-depth chuck interaction research, we improved chewout and spin-out resistance with this technology, providing you:

- Up to 100% torque resistance

- Decreased machinery downtime and scrap

- More reuse of cores

- Reduced vibration and web breaks from chewout issues during splicing

- Improved plant floor safety

- Enhanced product protection

Full-Service Packaging Advantage of Sonoco

Partner with a full-service packaging company equipped to customize solutions that fit your products and equipment. Sonoco’s paper and converting mill network provide built-in contingency across and supply security across our strategic global operations. With a state-of-the-art laboratory, we can prove core concepts before production, improving production efficiency, line speeds, product protection and more.

Sustainable Core Solutions That Promote Circularity

Reduce your carbon footprint, decrease landfill costs and advance your sustainability goals. Sonoco promotes circularity with sustainable practices and core products:

- Producing every fiber core with uncoated recycled paperboard on machines and in mills that use less water and energy.

- Decreasing damage and reuse of our high-performing, durable film cores when operations speed and slow during the normal course of winding and unwinding.

- Partnering with customers to return trim scrap and used cores back into the recycling stream.