In-Mold Labeled (IML) Containers

In-Mold Labeled (IML) Containers

Sonoco offers in-mold (IML) container design, prototyping, production and assembly services—delivering high-quality tubs for leading CPG brands.

IML Plastic Packaging

In packaging, in-mold labeling (IML) means the label is made of the same material of the package and is melted into the package thus making it recyclable. This creates IML packaging that is durable, efficient and sustainable. By combining decoration with structure, IML tubs and containers protect graphics from wear, reduce material use and shorten production time. Unlike glued-on paper labels, which can peel or fade, IML containers keep graphics durable and integrated for the life of the package.

How IML Plastic Packaging Supports Your Sales Goals

Stand-Out Visual Appeal

- Premium look and feel with high-quality graphics, metallic inks and embossing

- Product visibility through clear or windowed IML containers

- Brand differentiation with a wide variety of shapes that command attention on the shelf

Safety & Efficiency

- Built-in safety with tamper-evident designs—no membranes, shrink bands or detachable parts required

- Improved efficiency with stackable, lower-cube IML tubs that reduce shipping costs

Operational Compatibility

- Designed to run seamlessly on your existing production assets

Sustainability

- Made with 100% recyclable polypropylene, supporting your sustainability goals without compromising performance

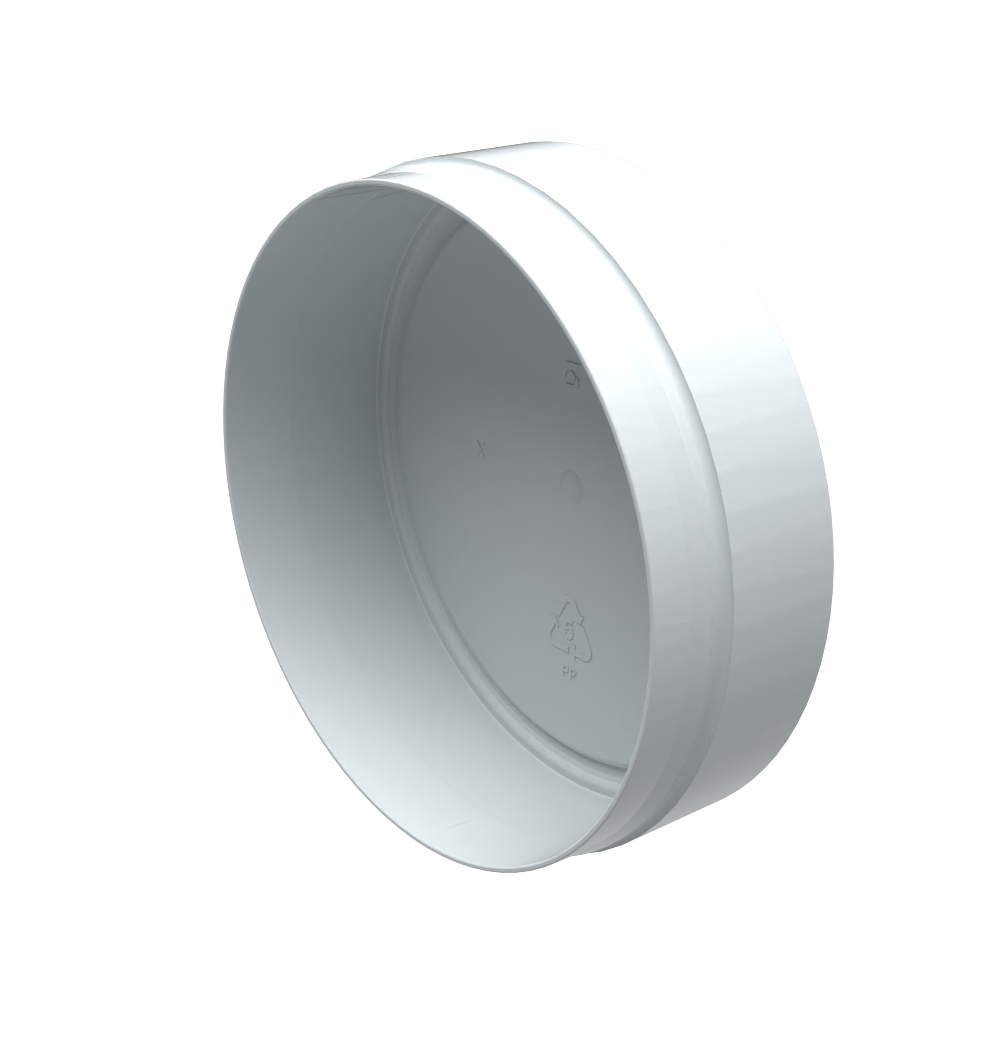

A Smarter 3-Piece Can for Consumer and Pharmaceutical Packaging

Sonoco’s FSSC 22000-certified 3-piece can is designed for safety, efficiency and sustainability. With a dual-compartment structure and recyclable materials, it provides reliable performance while supporting operational and environmental goals.

- Flexible dual-compartment design with two separate moisture-resistant compartments

- Compact size: 2.75” (70mm) in diameter and 0.940” (24mm) in depth

- Eco-friendly material: single-resin construction, recyclable where collection infrastructure exists

- Made in the USA, supporting local manufacturing and reducing carbon footprint

- Just-in-time supply management to optimize inventory levels and lower storage costs

- Efficient design that minimizes waste and reduces corrugate use

- Stackable structure for easier transport, storage and product protection

- Packaging designed for easy, single person loading into the pouch packaging equipment

3 Piece Lid

3 Piece Cap

3 Piece Body

Serving global customers in a global world.

We offer injection molded tub design, prototyping, mold-making, production and assembly in the U.S., Mexico, the Netherlands and Germany. No one is more committed than we are to meeting our customers’ needs around the world.

More than 50 years ago, Sonoco was one of the first to venture into the brand new technology of injection molding. Today, we maintain a focus on innovation, making 95% of our products with custom injection molds.