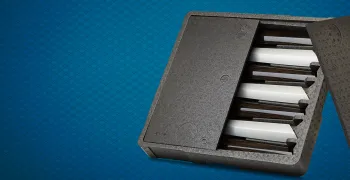

Protective Packaging

Protecting Your Products, from Creation to Consumption

Moving your products from the manufacturing floor to the retail floor, and everywhere in between, requires a diverse range of protective packaging solutions. Whether you are making and transporting durable goods like refrigerators, washers or electronics, shipping valuable pharmaceuticals or biologic products, or integrating materials to make automotive components, we have a protective solution to prevent damage, while ensuring product integrity throughout the rigors of the distribution cycle.

Connect with Sonoco

Work with us to find a solution to protect your product and prevent damages throughout the rigors of the distribution cycle.